Industrial Boilers

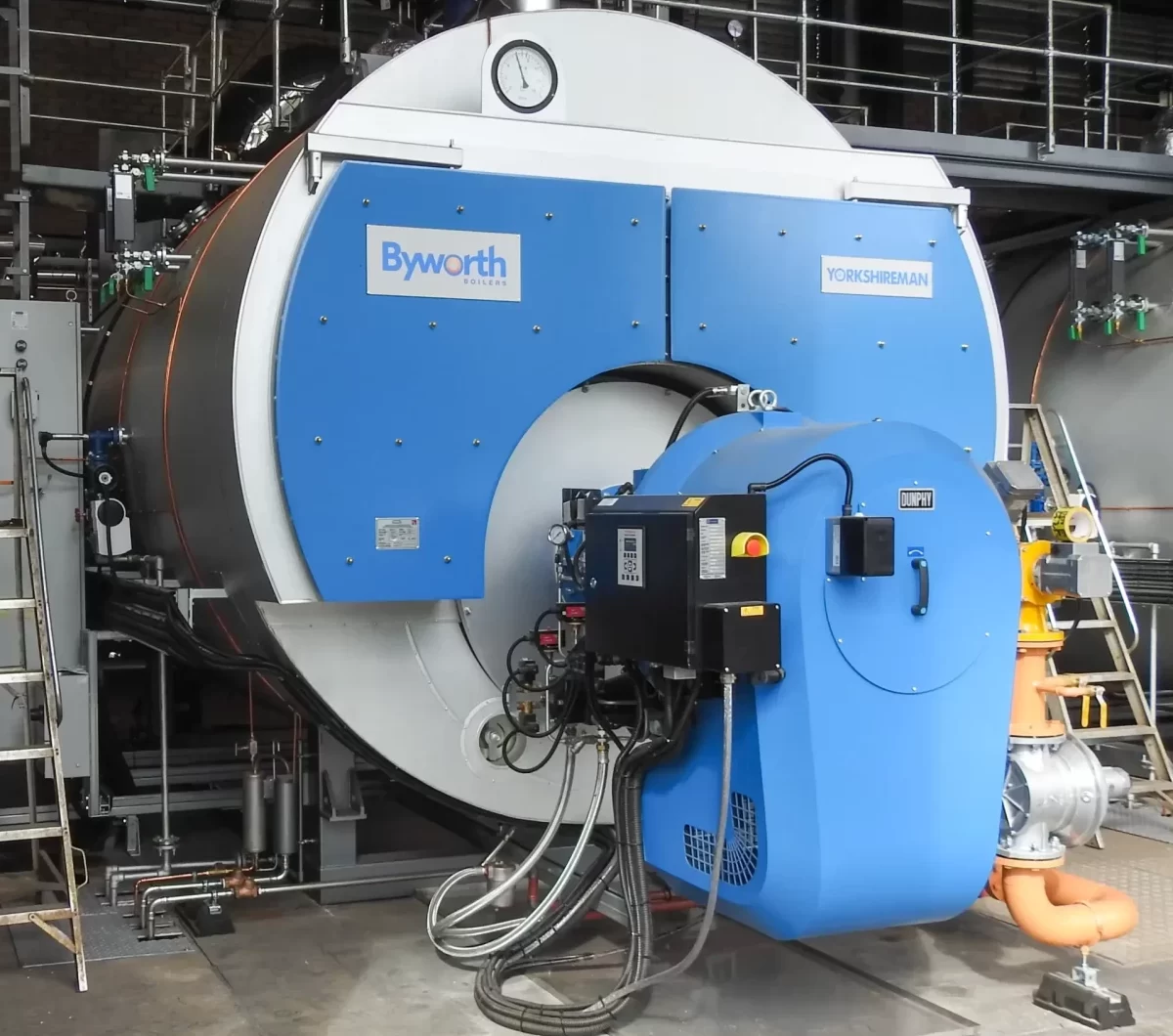

Industrial boilers are at the core of any boiler house, providing the energy needed for a wide range of applications. For optimised performance, they can be seamlessly integrated with advanced industrial gas burners. Our boiler systems combine advanced combustion engineering, digital control technology, and sustainable fuel compatibility to deliver maximum efficiency and long-term reliability.

With over 60 years of expertise in combustion and thermal engineering, we possess a deep understanding of how boiler systems operate, enabling us to source and install boilers of any size to meet your specific needs.

Over the decades, we’ve built strong partnerships with leading boiler manufacturers across the UK and internationally. Whether you require a steam boiler, industrial hot water boiler, or a fully electric steam boiler, our team designs each system around your pressure, temperature, and load profile.

Get in touch to learn more.